Research & Development

The Lab

In our candle manufacturing laboratory, we blend technical expertise with creative innovation to refine our craft. Our team of candle specialists meticulously hand-selects the perfect wick for each candle variant, ensuring a pristine burn and enhancing fragrance dispersal for an exceptional experience.

Color Testing

Color testing is a critical step that ensures each candle meets the highest standards of aesthetic appeal and quality. This procedure involves blending dyes and pigments with wax to achieve a precise and consistent color. Technicians then evaluate the candles under various lighting conditions to confirm that the hues are vibrant, true to the intended shade, and free from imperfections.

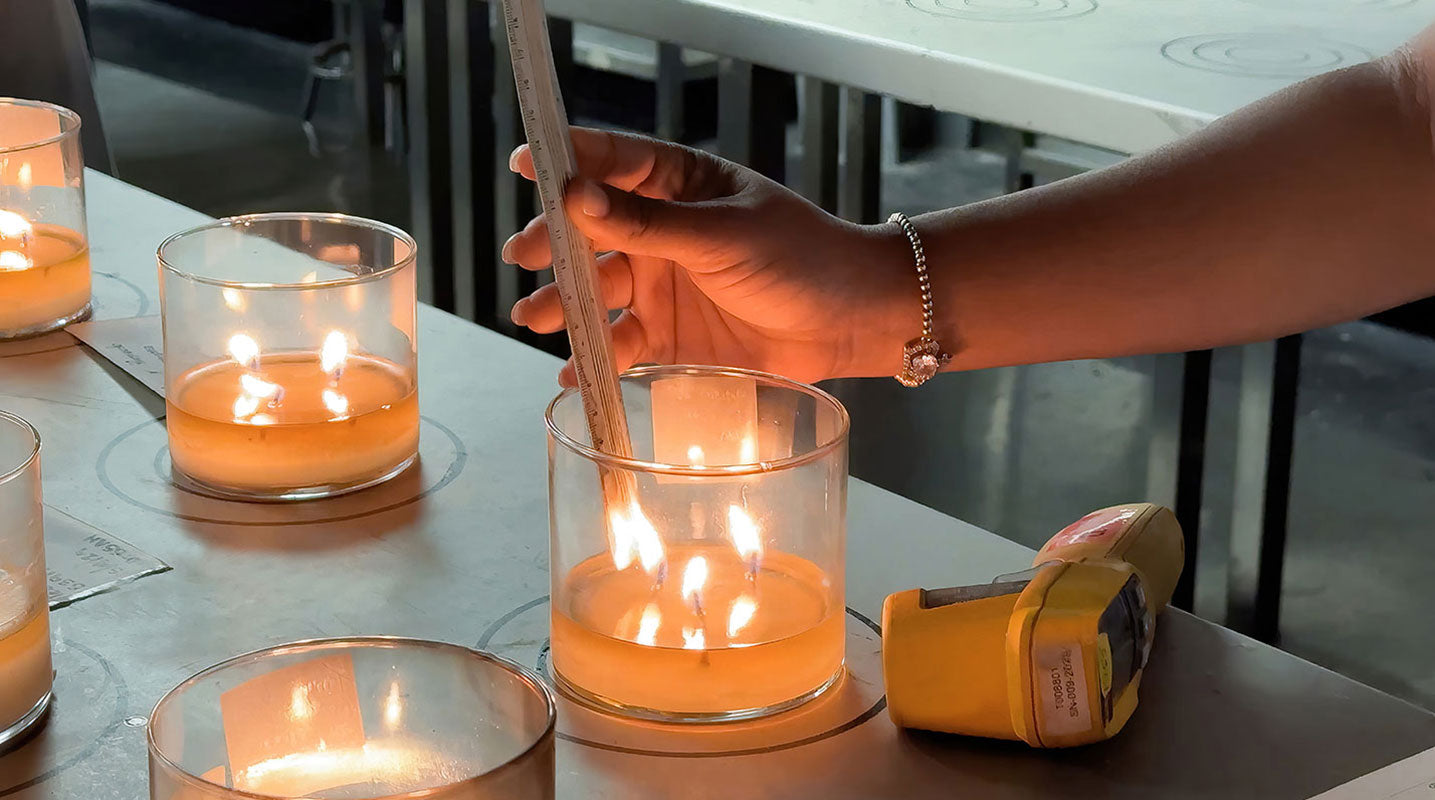

Burn Testing

As candle manufacturers in the Dominican Republic, we adhere to ASTM standards for burn testing. Our team measures heat and soot levels in each candle to ensure quality and safety. Additionally, we have a dedicated laboratory where we conduct burn testing according to ASTM standards, analyzing heat and soot emissions in every candle.

Inspections

We inspect all batches of raw materials that go into Velas candles. We audit all incoming materials from candle containers to master cases using the military table level II sampling plan, AQL 1%.

Laboratory Work

We do in-house lab testing for paraffin, fragrances, wick, adhesives and additives in order to offer optimum quality control. As a leading candle manufacturer in the industry, we must ensure our candles are up to par with our competition.

Gather & Assemble

Our experienced team of fragrance evaluators, product development and production experts, source the best components required to ensure a high quality product with great value.

Wick Optimization

Our lab specialists assist our designers and customers choose the right wick for each candle to achieve the cleanest burn and optimal fragrance.